SMG Group has a strong team of steel making technicians who are skilled in the steelmaking process and have extensive experience in delivering complete converter steelmaking projects. According to the different needs of the customers, SMG Group can provide customized solutions to meet the different capacity requirements of customers.

Converter steelmaking process usually takes hot metal, scrap steel and ferroalloy as the main raw materials, without the aid of external energy, relying on the physical heat of molten iron itself and the chemical reaction between liquid iron components to generate heat and complete the BOF steelmaking process in the converter.

.jpg)

According to different refractories, the basic oxygen converters are divided into acid and basic; According to the part of gas blowing into the furnace, there are top blowing, bottom blowing and side blowing; According to the gas type, it is divided into air converter and oxygen converter. The basic oxygen top blown and top and bottom blown converter is the most commonly used steelmaking equipment because of its high production speed, large output, high single furnace output, low cost and less investment. Converter is mainly used for the production of carbon steel, alloy steel and copper and nickel smelting. Oxygen lance is one of the main process equipment in oxygen converter steelmaking, and its performance characteristics of oxygen lance directly affect the smelting effect and blowing time, thus affecting the quality and output of steel.

.jpg)

Usually, oxygen top-blown converter is the most common steel making equipment in converter. The entire basic oxygen process is as follows:

.jpg)

First put the scrap steel into the furnace, then pour the hot metal, and add the appropriate amount of slag-making materials (such as quicklime, etc.). After feeding, the oxygen lance is inserted into the furnace from the top of the furnace, and the oxygen is blown into the air (hyperbaric oxygen with a purity greater than 99%), so that it directly oxidizes the hot metal with high temperature to remove impurities. The replacement of air with pure oxygen can overcome the disadvantages of brittleness of steel due to the influence of nitrogen in the air, and the removal of heat by nitrogen. After removing most of the sulfur and phosphorus, when the composition and temperature of the molten steel meet the requirements, the blowing is stopped, the spray lance is raised, and the steel is ready to be produced. The converter furnace body is tilted, the molten steel is injected into the ladle from the outlet, and the deoxidizer is added to deoxidize and adjust the composition. After the molten steel is qualified, it can be poured into steel castings or ingots, and the ingots can be rolled into various steel products.

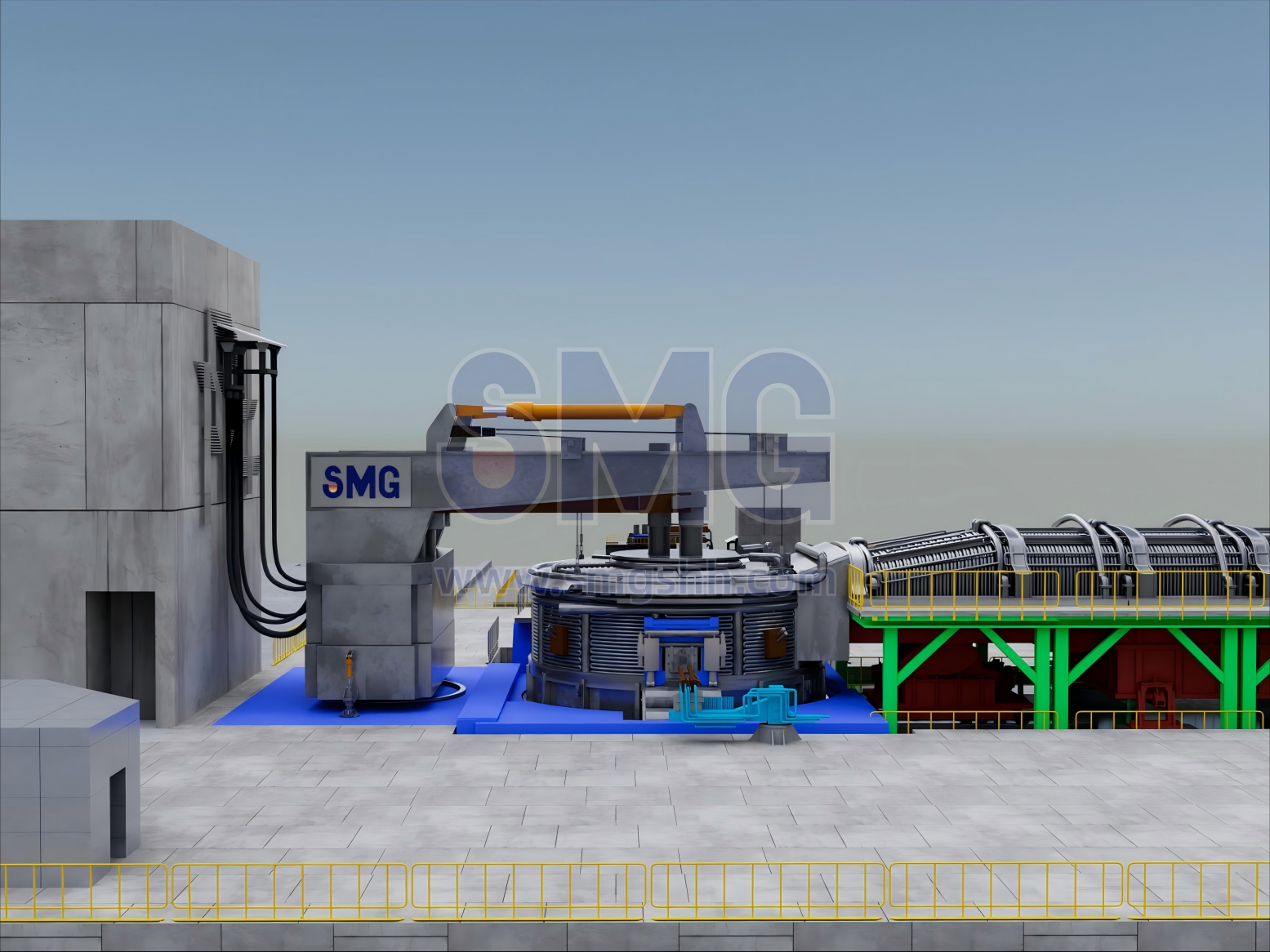

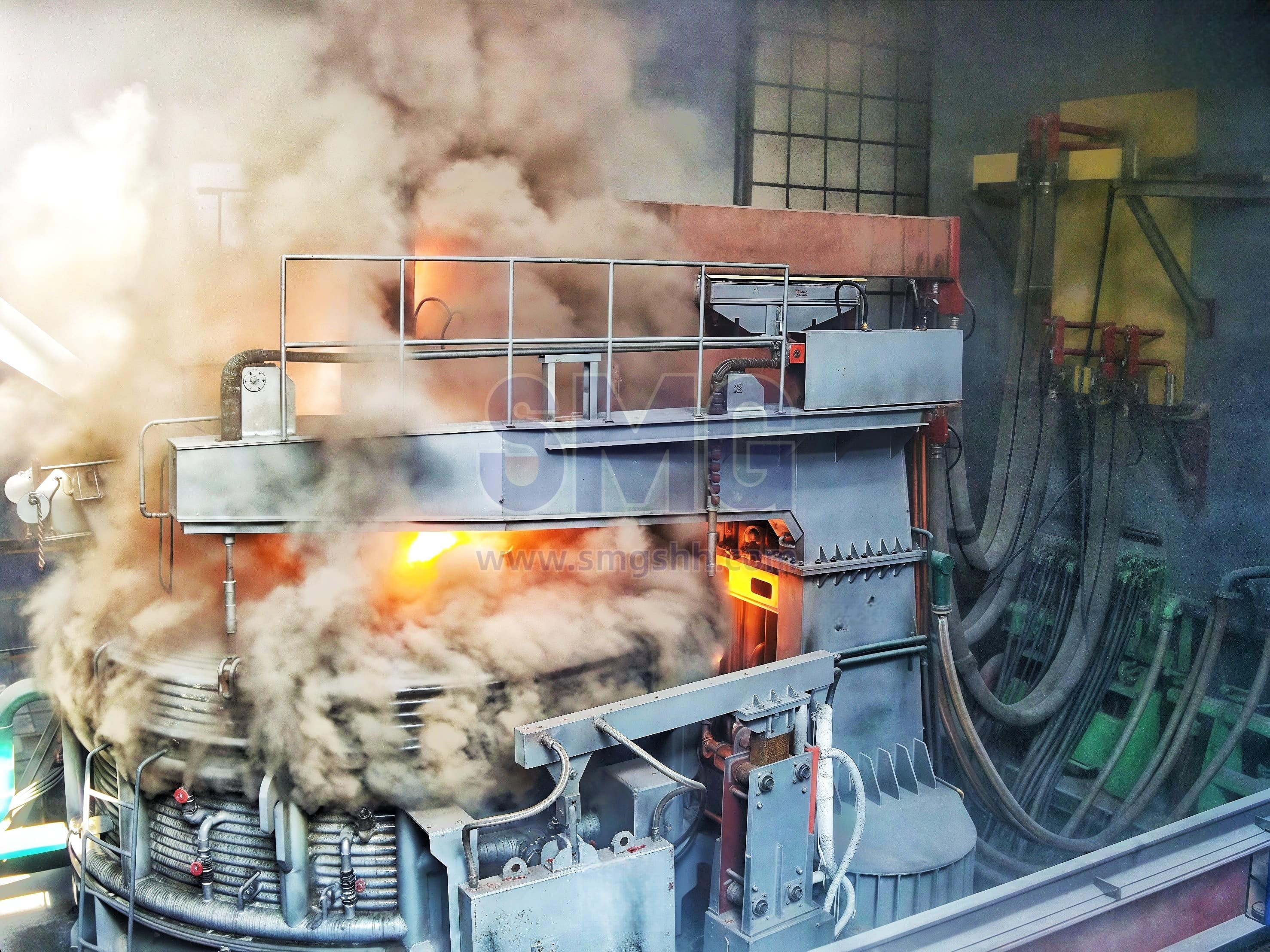

SMG Group masters the mature process of EAF furnace steelmaking and specializes in providing customers with a full range of cost-effective electric smelting furnace equipment, including electric arc furnaces, submerged arc furnaces, refining furnaces and continuous casting machines. EAF oxidizes excess impurities such as carbon, silicon and phosphorus in molten steel by blowing oxygen (O₂) (similar to BOF, but with more flexible scale). Compared with the Basic Oxygen Furnace (BOF) steelmaking, BOF relies on blast furnace pig iron (high carbon), while EAF mainly uses scrap steel /DRI (low carbon). EAF can flexibly adjust the alloy composition (such as in stainless steel smelting).

SMG Group provides two types of EAF, one is the top charging EAF furnace, the other is the horizontal continuous charging EAF furnace, also known as consteel electric arc furnace. EAF can use reduced iron (DRI) as raw material. DRI is solid sponge iron (Fe) obtained from reduced iron ore, with a low carbon content, which is suitable for EAF smelting.

.jpg)

According to the specific needs of cast steel, we have customized equipment configuration for customers, such as AOD furnace, VOD furnace, LF, etc. It can meet the needs of customers to produce steel including ordinary carbon steel, stainless steel and other grades of steel.

(1).jpg)

Electric energy is used as heat source in EAF, which avoids the large amounts of pollution of steel caused by sulfur content in gas heat source. The operation process is flexible, and the slag and gas can be controlled to oxidize or reduce; Strong reducibility can make the precious elements contained in the charge chromium, nickel, tungsten, molybdenum, vanadium, titanium and so on rarely burn; High furnace temperature, easy to control; The product quality is high.

Ladle refining furnace (LRF) refers to the equipment that combines the heating and refining function of a steel smelting furnace. It is used for the molten steel inclusion modifications in the primary melting furnaces (electric arc furnace, open hearth furnace, basic oxygen furnace bof), and can adjust the temperature of molten steel, process buffer, and meet the important metallurgical equipment of continuous casting and continuous rolling. Secondary refining treatment is mainly carried out in the ladle furnace.

.jpg)

.jpg)

3. Vacuum degassing. After the ladle is lifted into the vacuum tank, the vacuum degassing is carried out by steam jet pump. At the same time, argon gas is blown into the bottom of the ladle to stir the liquid steel. The hydrogen content and nitrogen content in the liquid steel can be removed, and the oxygen content and sulfur content can be further reduced, and the liquid steel with high purity and superior performance can be obtained.

.jpg)

The application of ladle refining furnace for the whole enterprise can at least increase the following benefits: accelerate the production rhythm and improve the entire metallurgical production efficiency.

.jpg)