SMG Group has constantly designed and supplied reliable and professional color coating production lines for customers. According to different requirements for the production lines, SMG Group can offer tailor-made color coating solutions.

With more than 24 years of rich experience in metallurgical projects, SMG Group has persistently improved the expertise of technical engineers in cold rolling mill, and is dedicated to providing every customer with high-quality and reliable cold strip production line project solutions according to the requirement of customers.

.jpg)

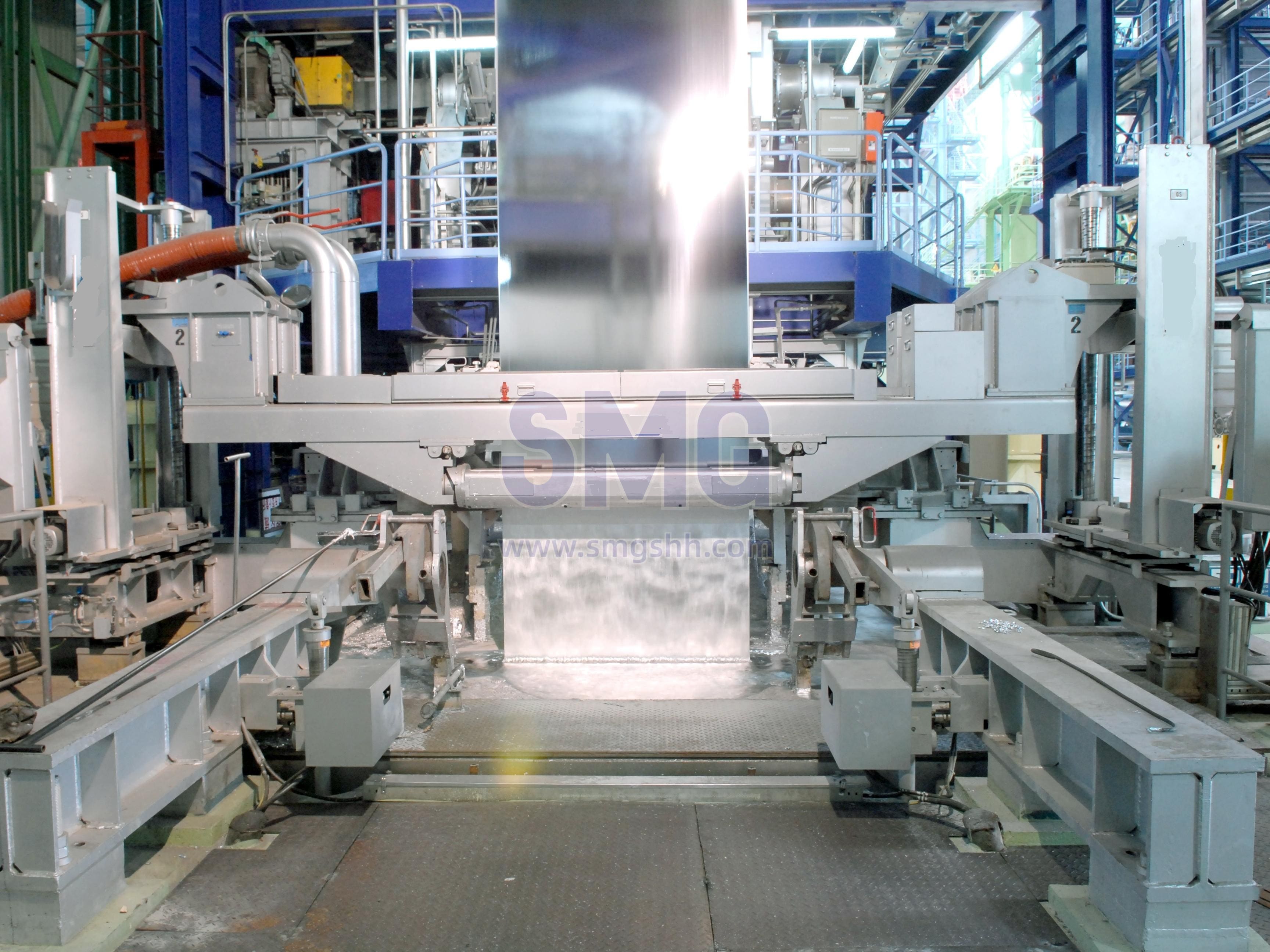

Cold rolling is usually done longitudinally. The process of cold strip production line generally includes raw material preparation, pickling, rolling, degreasing, annealing (heat treatment), finishing and so on.

.jpg)

Cold rolling mill process takes hot strip as raw materials, and phosphorus should be removed before cold rolling to ensure that the surface of cold strip is clean. Rolling is the main process that deforms materials. The purpose of degreasing is to remove the lubricating grease attached to the rolled material during rolling, so as not to pollute the steel surface during annealing, and to prevent the carburization of stainless steel. Annealing includes intermediate annealing and finished product heat treatment. Intermediate annealing is to eliminate the work hardening caused by cold deformation through recrystallization to restore the plasticity of the material and reduce the deformation resistance of the metal. The purpose of heat treatment of the finished product is to eliminate hardening through recrystallization. It is also based on the technical requirements of the product to obtain the required organization (such as various textures, etc.) and product properties (such as deep drawing, electromagnetic properties, etc.). Finishing includes checking, cutting, straightening (leveling), printing, sorting and packaging. Cold-rolled products have high packaging requirements to prevent the surface of the product from being scratched during transportation.

.jpg)

Since the cold rolled strip is obtained after the hot rolled strip goes through the cold rolling processes, and the cold rolling will also carry out some surface finishing, the cold strip is better than the hot strip in the surface quality (such as surface roughness, etc.), so if there are higher requirements for the coating quality of the product after the sequence of painting, generally choose the cold rolled strip, and the hot rolled strip is divided into pickling plate and unpickling plate. Pickling plate surface has a normal metal color due to pickling, but unpickling plate usually has an oxide layer on the surface, or there is iron oxide black layer, popular speaking is the fire like, and if the storage environment is not good, usually with some rust.

.jpg)

.jpg)

SMG Group is committed to designing and supplying reliable and professional galvanizing production lines for customers. According to different requirements for galvanized steel sheet, SMG Group can offer specific turnkey galvanizing project solutions that meet the needs of each customer.

.jpg)

.jpg)

Galvanizing process refers to the surface treatment technology of zinc coating on the surface of sheet metals, alloys or other materials to play the role of aesthetics and rust prevention. The main method is hot dip galvanizing. The hot galvanized steel sheet has good corrosion resistance and aesthetics, and is suitable for a variety of high outdoor and durability requirements of engineering and construction projects.

.jpg)

The process flow of a galvanizing production line usually includes the following steps: preparation work, surface treatment, galvanizing, cooling and packaging. First of all, the steel needs to be cleaned and prepared for oil removal to ensure a clean surface. This is followed by surface treatment, which usually includes methods such as hot dip galvanizing or electro-galvanizing to form a protective layer of zinc on the sheet metal surface for corrosion protection. After galvanizing is completed, the galvanized metal needs to be cooled so that it reaches the right temperature before being packaged for transportation and storage. These steps usually require strict control and monitoring to ensure the production of high-quality galvanized steel sheet which can prevent rusting.

.jpg)

.jpg)

SMG Group is committed to designing and supplying reliable and professional color coating lines for customers. According to different requirements from the clients, SMG Group can offer tailor turnkey coating project solutions. Color coated sheet uses a cold-rolled steel plate and galvanized sheet as the substrate, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), in a continuous way coated with paint (roll coating method), after baking and cooling. Paint can be one or more layers of liquid paint, rich in color. Color coated plate is mainly used in construction, home appliances, transportation and other fields.

.jpg)

The process of the coil painting system typically includes the following steps: surface treatment (such as rust removal, degreasing), primer coating, intermediate drying, topcoat coating, final drying, inspection, and packaging. These steps can be adjusted and optimized according to the specific product and production line requirements.

.jpg)

The process of the color coating production line aims to ensure the adhesion, corrosion resistance, and appearance quality of the coating, meeting the needs of customers and industry standards.

.jpg)