Date: 2025/8/4

Category: Metallurgical encyclopedia terms

Views: 449

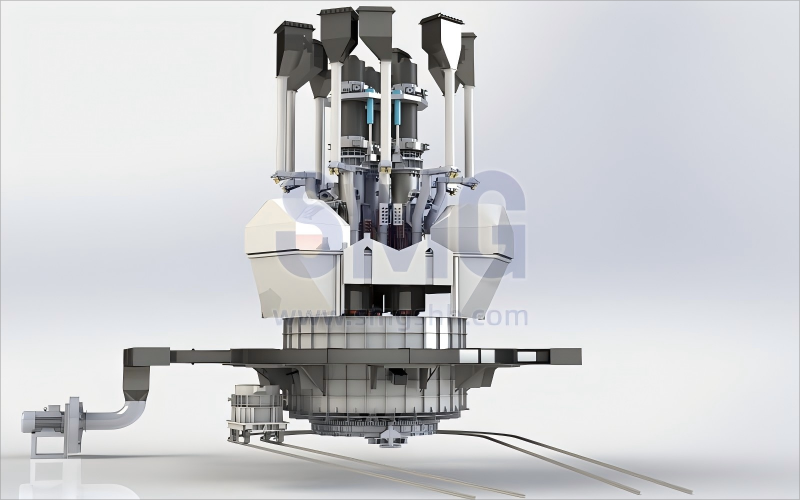

In the grand symphony of steel smelting, silicon-manganese alloy plays an irreplaceable role as a "purifier" - efficiently deoxidizing and desulfurizing to enhance the purity and quality of molten steel. The core equipment that bears this significant mission is the uniquely structured silicon-manganese alloy submerged arc furnace.

This kind of giant metallurgical equipment, with its towering self-baking electrodes deeply penetrating into the furnace, generates intense electric arcs under powerful currents, instantly creating a molten pool with a temperature close to 2000℃. Manganese ore, silica, coke and other raw materials, carefully proportioned, are continuously fed into the furnace. Under the combined effect of high temperature and coke as a reducing agent, the manganese and silicon elements in the ore are efficiently reduced and smelted together, eventually forming liquid silicon-manganese alloy, which flows out from the bottom of the furnace, is cooled and cast into ingots, becoming the cornerstone of metallurgical production with a capacity of tens of thousands of tons.

The high efficiency of the submerged arc furnace stems from its "buried arc operation" design: the electrodes are deeply embedded in the material layer, resulting in high electrical energy conversion efficiency and concentrated, stable heat. However, operating this high-temperature giant furnace is also full of challenges - precise electrode control, dynamic balance of furnace conditions, and long-term maintenance of the furnace lining all test the wisdom and experience of the operators. At the same time, the huge energy consumption and emission issues also drive the industry to continuously explore in the directions of waste heat utilization, intelligent control, and more environmentally friendly processes.

The submerged arc furnace for silicon-manganese alloy, this silent and towering energy conversion device, supports the framework of modern steel industry with the flow of molten metal. In the future, driven by both efficiency improvement and environmental friendliness, it will continue to evolve, infusing steel with purer strength.

Phone

Address